How Generative AI is Revolutionizing Core Banking and Financial Services...

Read MoreSAP Services

Enabling business transformation through end-to-end SAP services

Enterprise Solutions

Empower your enterprise with agile, integrated platforms.

AI, Data & Insights

Turning intelligence into action with real-time insights

Smart Manufacturing & IIoT

Driving efficiency through smart, connected technologies.

Product Engineering & Modernization

Accelerating innovation through agile, modern solutions

Enable seamless growth with secure, cloud-native solutions

Enabling business transformation through end-to-end SAP services

Automatic customer code remediation for S4 HANA migration

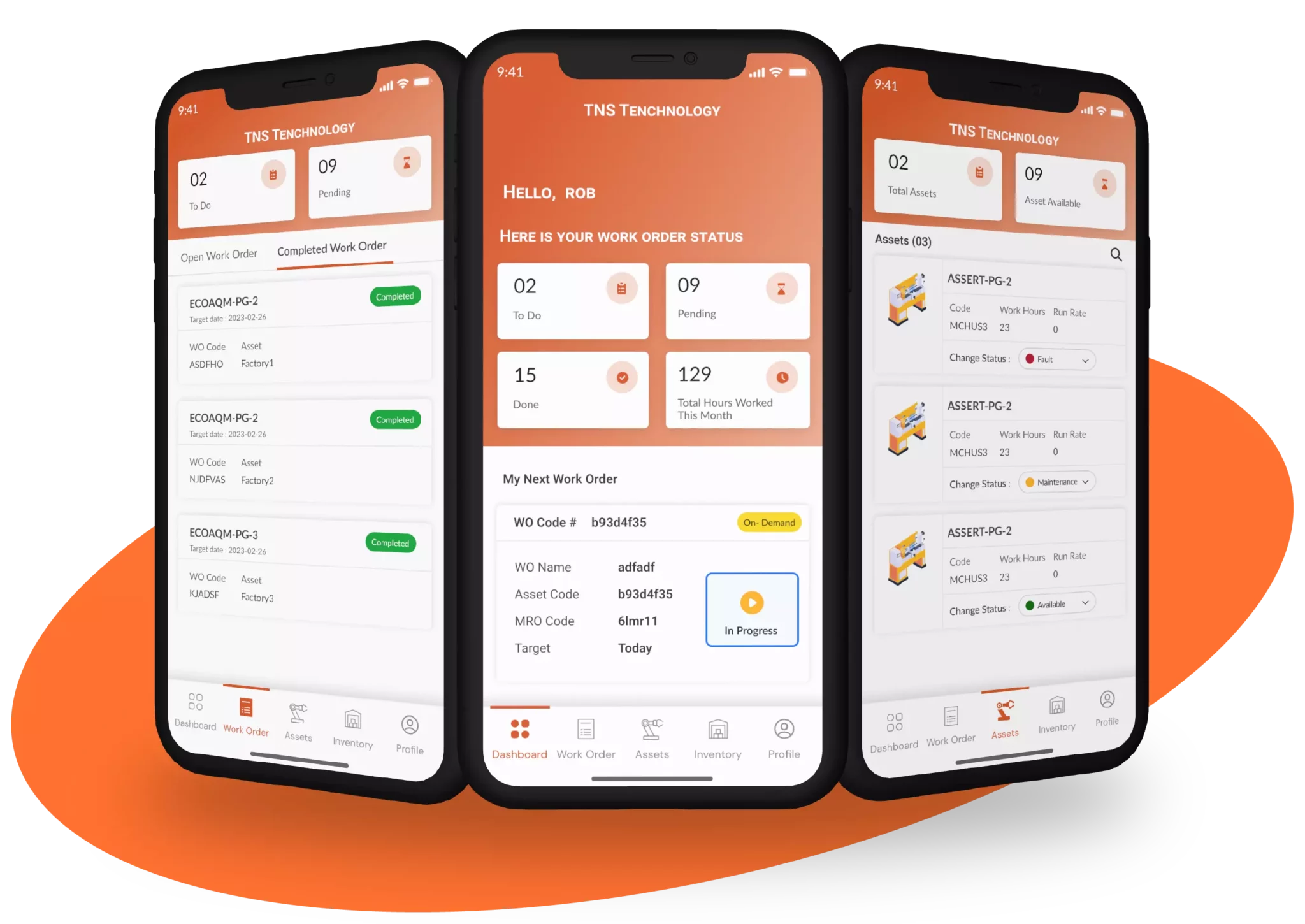

Ready to deploy industrial IoT

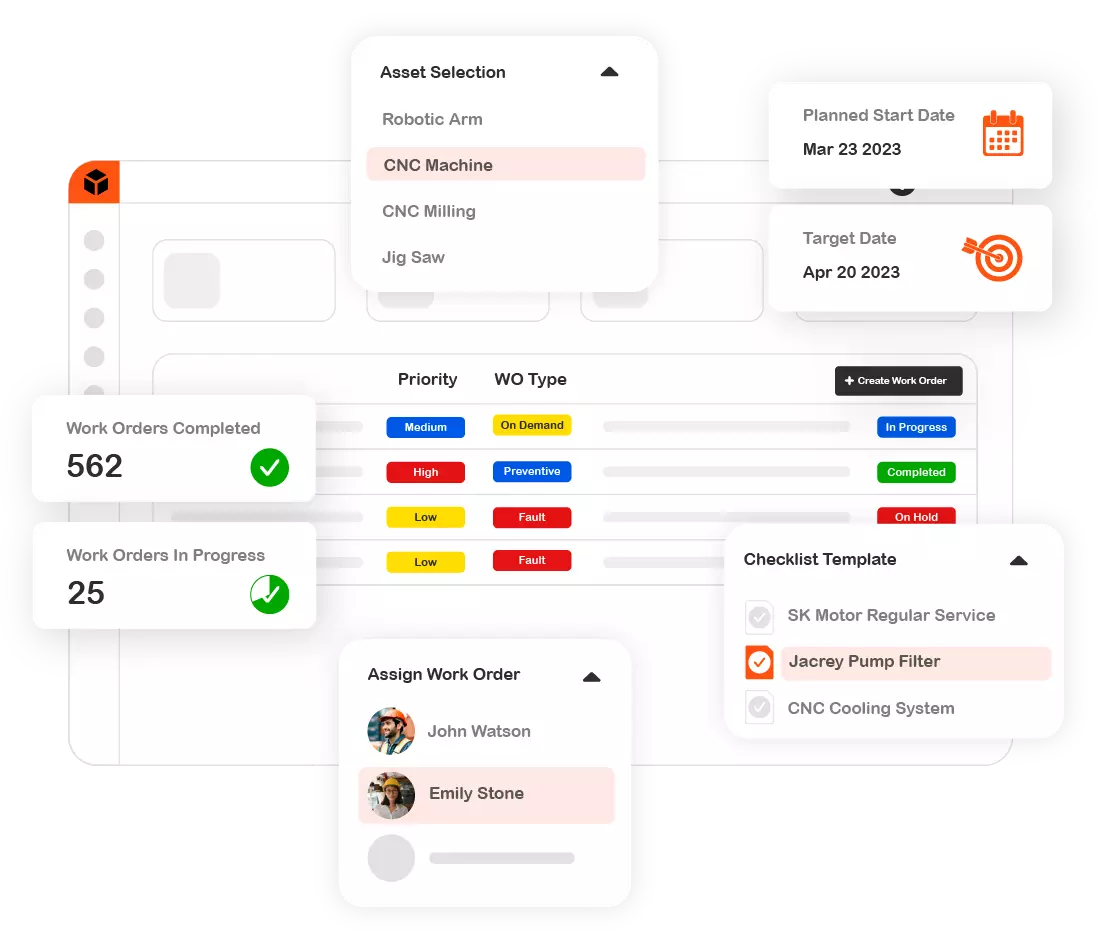

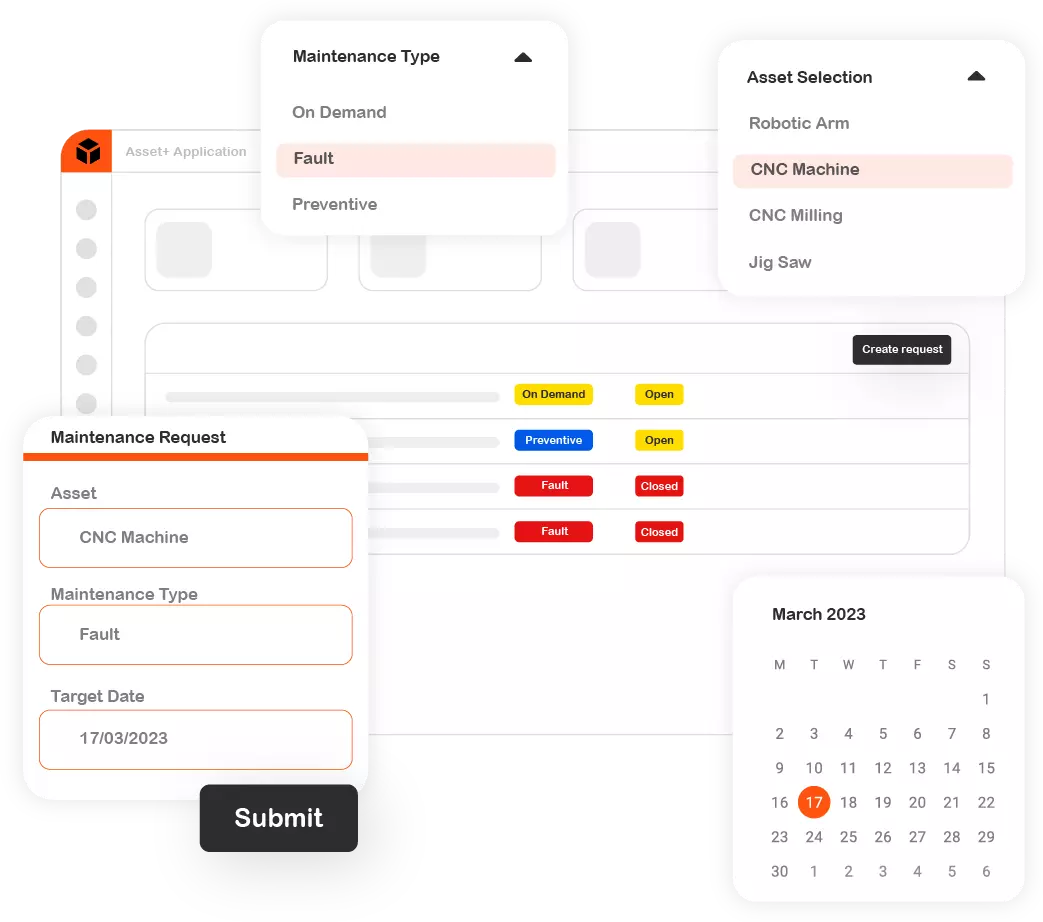

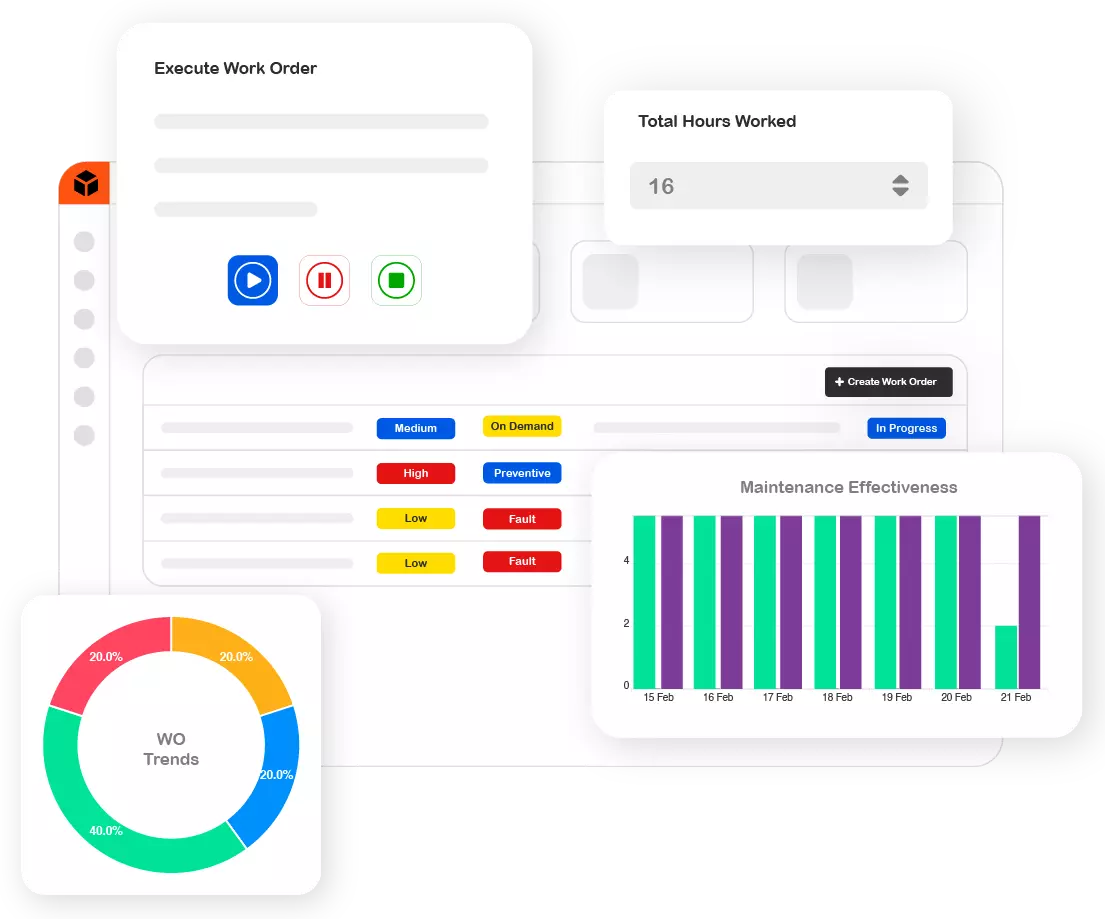

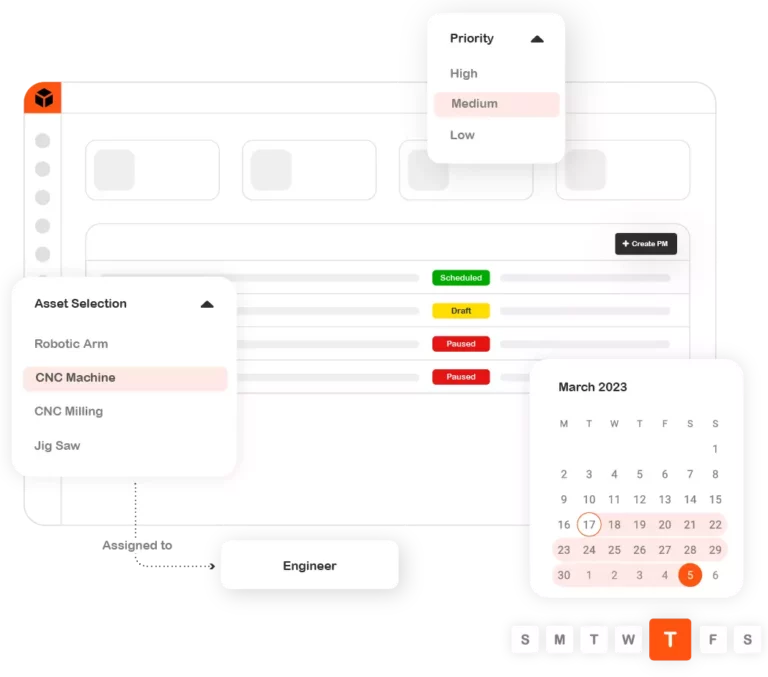

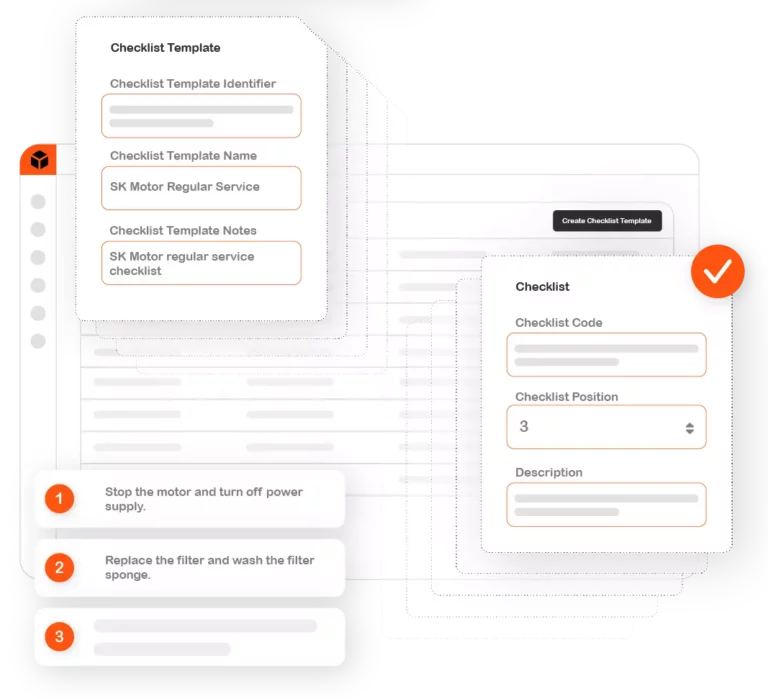

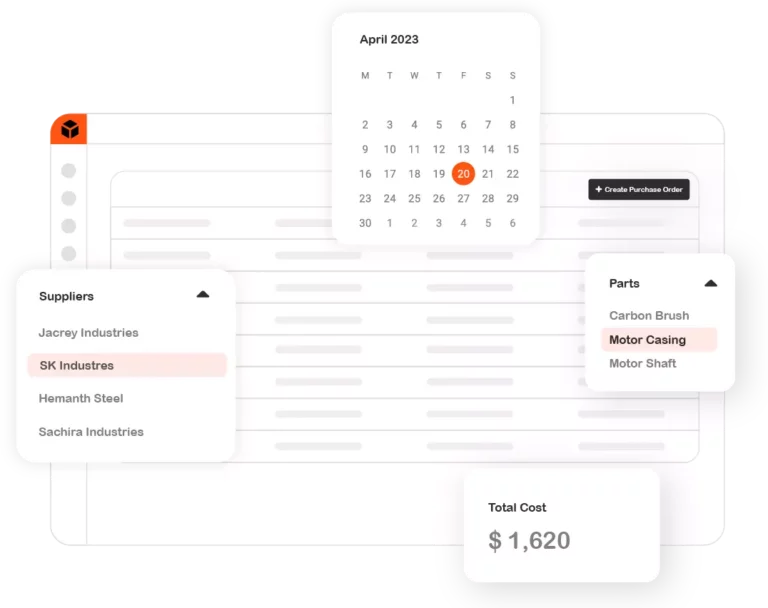

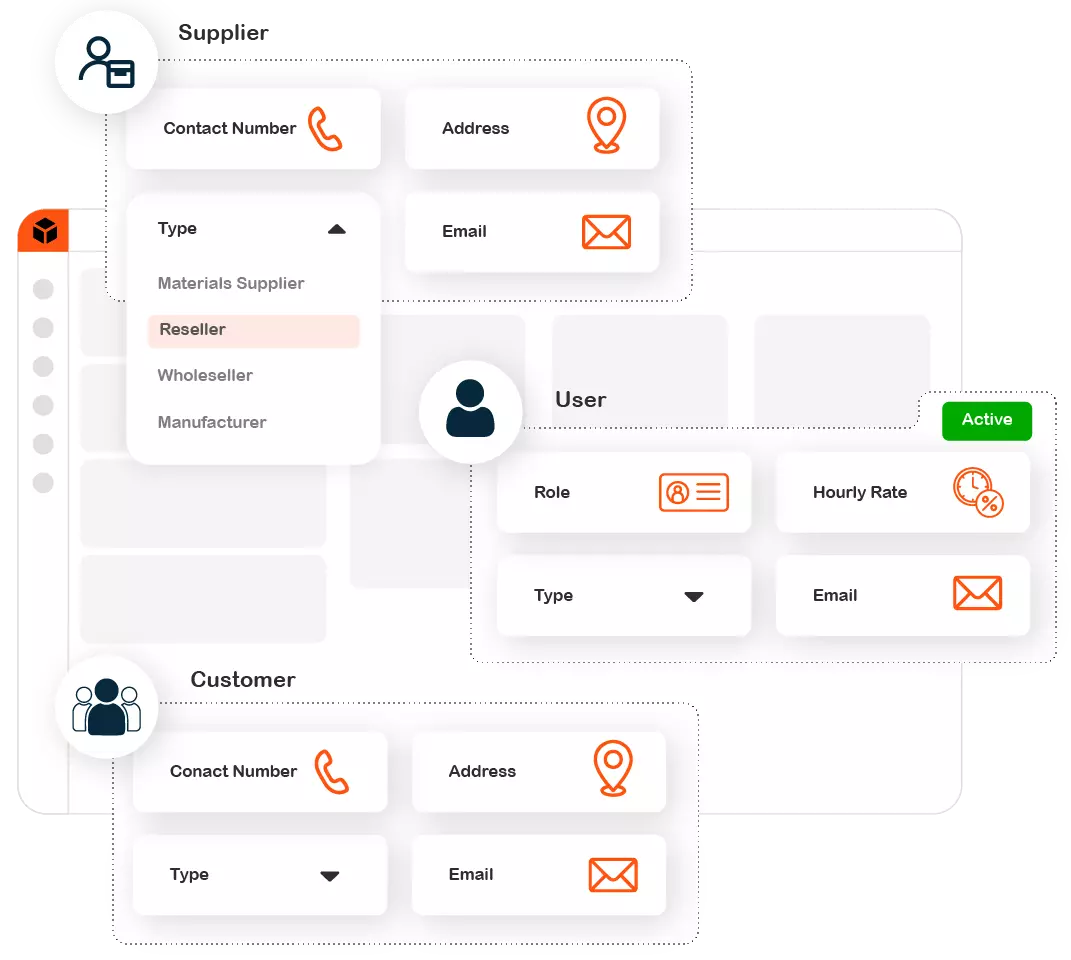

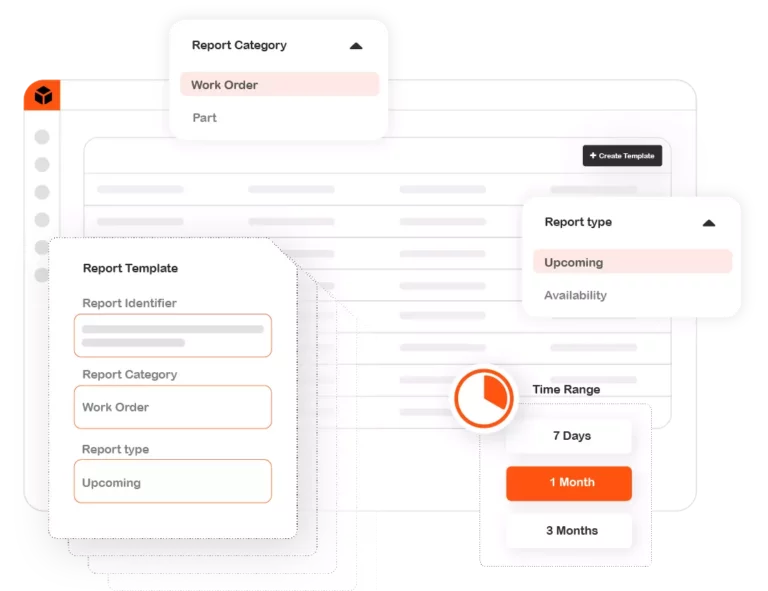

CMMS for smarter machine maintenance

Multi-channel response automation

Case Studies

See how our expertise and partnerships empower businesses to achieve measurable success and accelerate innovation.

Read Success StoriesBlogs

Explore insights, trends, and thought leadership shaping the future of technology and business.

View all blogsTransform Your Business with Boomi’s AI Integration

Transform Your Business with Boomi’s AI Integration In an era...

Read MoreEmpowering Businesses with Innovation: Intellioz and IBM

Empowering Businesses with Innovation: Intellioz and IBM At Intellioz, we...

Read More